JKS Incorporated is growing!

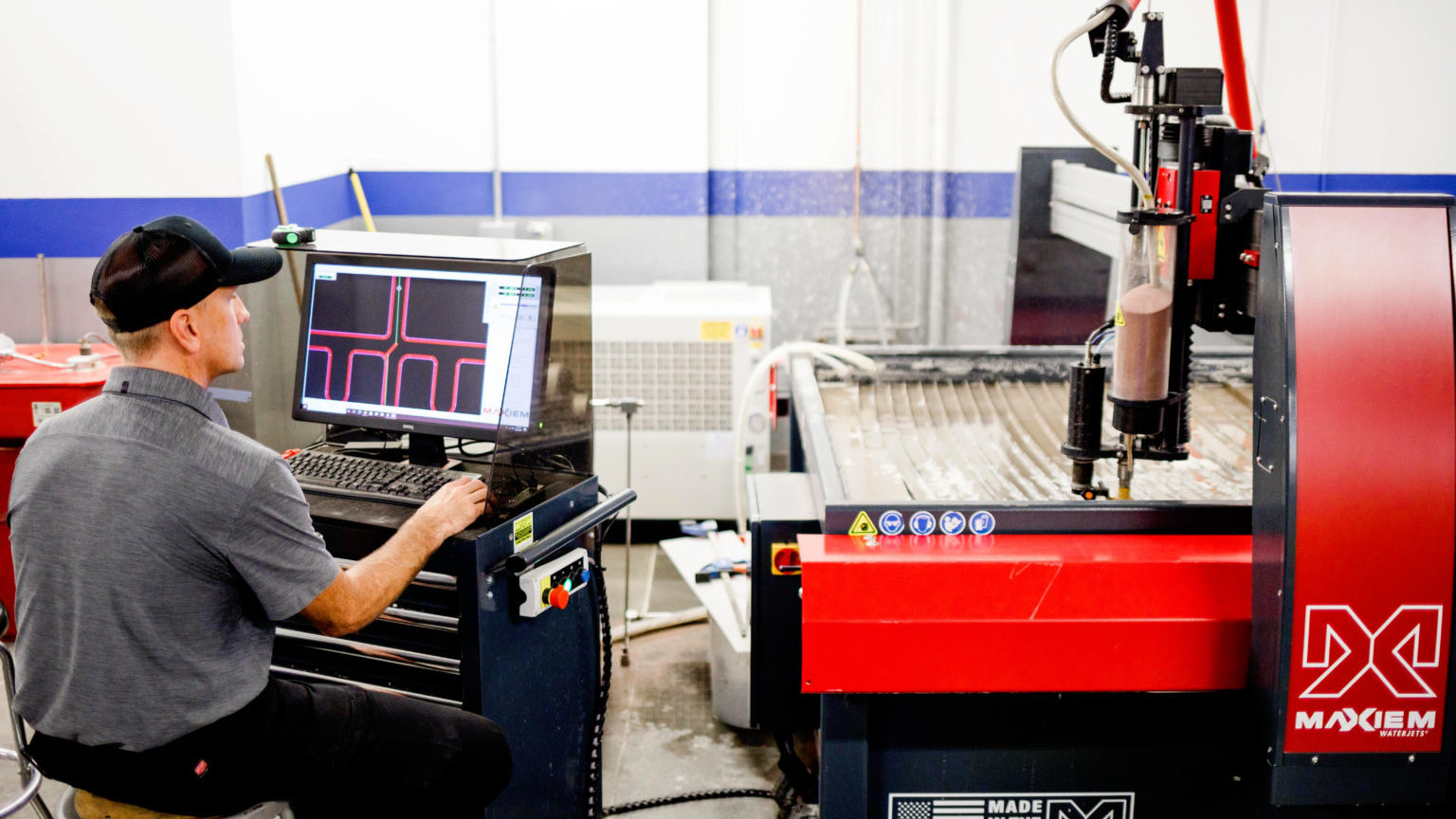

We are excited to announce that we have expanded our fabrication department. This is all made possible by the addition of a new member to our JKS family… and a new Omax waterjet.

Michael Tennyson, who joins us as our new Director of Fabrication, has been welding and fabricating professionally for more than 25 years. He previously worked at Richard Childress Racing where he served as the Director of Fabrication and oversaw all of RCR’s fabrication operations, including the building of suspension components and chassis, body and paint work, and the final fabrication assembly of stock cars.

“Coming from the racing world, everything you do has to be extremely high quality and done in a timely manner with zero room for failure,” said Michael. “In that kind of position, you have to know a little about a lot of things—you also learn something new every day”

While JKS has always offered custom fabrication, our new waterjet and Michael’s skill set, talent, and training give us the ability to do more precision-based cutting and fabrication of parts for businesses, including the building of machines for automated processes unique to a company’s production. We also plan to add a hydraulic press brake to our production space soon.

“Our fabrication abilities are now all but limitless with the resources we have available,” said Michael. “Our new Omax waterjet has the capability to cut virtually any material with a thickness of up to 12 inches.”

Christy Cox Spencer, president of JKS, says she is happy to have Michael join the team and is looking forward to working with new clients in a new field.

“We’ve known Michael since 2004—he is a brilliant man who is capable of running our entire fabrication department,” said Christy. “I’m excited about the opportunities that he and our new equipment and resources are going to bring to us.”

Oh, and did we mention that Michael’s dog, Charlie, will be in the shop on occasion? Looks like Christy’s dogs, Cal and Tray, have a little competition.

Oh, and did we mention that Michael’s dog, Charlie, will be in the shop on occasion? Looks like Christy’s dogs, Cal and Tray, have a little competition.